Eurasian Resources Group improves performance of its Kazakhstan Aluminium Smelter to produce over 235,000 tons of primary aluminium in 2016

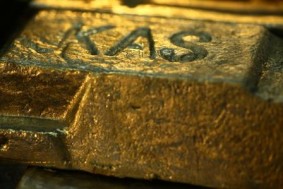

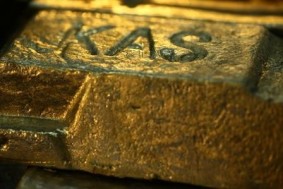

‘Kazakhstan Aluminium Smelter’ JSC (KAS), which is part of Eurasian Resources Group and is the only aluminium producer in the Republic of Kazakhstan, produced more than 235,000 tons of primary aluminium in 2016. The plant has improved its performance across many key indicators, exceeded the annual production target and achieved one of the highest production volumes in its nine year history.

KAS is capable of producing 250kt of aluminium per year and in 2016 employed more than 94% of its design capacity. This marks a production increase of 6.3% over 2015 levels - last year KAS has manufactured 221,593 tonnes of primary aluminium. In 2016 the daily output per reduction cell averaged 2,446 kilograms.

The electrolysis power consumption was improved from the design rate of 13,460 kWh to 12,746 kWh, an achievement made possible due to a lowering in the default voltage on reduction cells from 4.05 volts to 3.99 volts. KAS aluminium production efficiency is further evidenced by its yield, which currently stands at 93%. All these indicators are amongst the best in the world.

KAS uses cutting edge equipment to produce high-quality A-8 and A-85 grade products which have a trademark registered on the London Commodity Exchange. With exports accounting for approximately 90% of its output, the plant sells aluminium across Europe, Asia and South America, with its largest buyers based in Russia, Ukraine, Belarus, Azerbaijan and Uzbekistan. KAS is currently exploring options to produce aluminium alloys.

***

The production technology implemented at KAS is commended for excellence in innovation, has achieved significant environmental credentials and puts the plant among the top ten best aluminium manufacturers worldwide. The high quality of the process was recognised in December 2016 when KAS won a ‘Quality Leader’ prize at the Altyn Sapa Awards of the President of the Republic of Kazakhstan.

KAS is committed to supporting the environment and employs state-of-the-art prebaked anode technology as this is the most advanced, environmentally friendly aluminium production solution in use. In 2016 alone, KAS produced 136,000 tons of proprietary anodes.

The plant operates a closed waste management cycle and uses unique gas cleaning equipment manufactured by Alstom, which can capture up to 99.7% of all harmful atmospheric emissions. KAS also launched an ISO 50001 energy management system in 2014 and since then has reduced electrolytic aluminium power consumption by 1.4% vs. standard value, and by 2.7% vs. design value, bringing it to global best practice levels. Overall, in the nine years since the plant was commissioned, the power consumption required per ton of primary aluminium production has been reduced threefold.