Eurasian Resources Group plans battery material plant

ERG is considering the construction of a lithium-ion battery precursor plant, to be exclusively supplied with cobalt hydroxide from its Metalkol RTR facility in the DRC

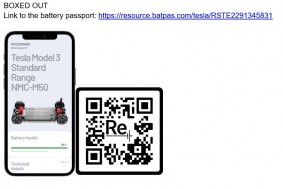

Vertical integration of ERG’s cobalt business aims to strengthen its position as a strategic supplier of traceable battery materials for the electric vehicle industry

Eurasian Resources Group (“ERG” or the “Group”), a leading diversified natural resources group, today announced it is assessing the construction of a battery material plant to produce nickel-cobalt-manganese (NCM) precursor materials for electric vehicles (EVs).

The Group is evaluating technical solutions offered by renowned engineering firms BGRIMM Technology Group from China and Outotec from Finland, which will allow for the production of both NCM 6:2:2 and NCM 8:1:1 precursors depending on market conditions. The Group is planning to develop the plant in two phases. The first phase is expected to produce 90,000 tonnes of NCM annually following a two-year construction period. The expansion will be defined depending on market conditions.

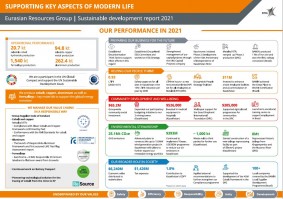

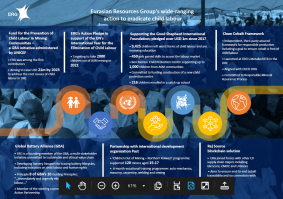

Benedikt Sobotka, CEO of Eurasian Resources Group, said: “Our vision for a green economy is at the core of our continued commitment to supply the most critical materials for the global battery sector and we are leading industry efforts to ensure the sustainable, traceable cobalt sourcing in supply chains across Europe, North America, South Korea and Japan. Together with our partners we are currently considering multiple locations for the development of the precursor plant.”

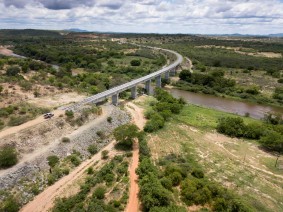

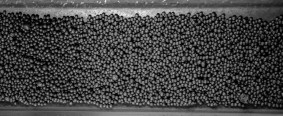

The precursor plant will be exclusively supplied with cobalt hydroxide from ERG’s Metalkol RTR in the Democratic Republic of the Congo, whose operations are in accordance with recognised responsible and sustainable practices as set out in the ERG Clean Cobalt Framework. Metalkol RTR is a historic tailings reclamation and environmental restoration facility producing high quality copper cathode and cobalt in hydroxide. It is positioned to become one of the largest producers of cobalt globally upon completion of its Phase II expansion.

For the precursor plant the Group plans to source nickel sulphate from third parties or produce it itself using nickel raw materials Mixed Hydroxide Precipitate (MHP) or Mixed Sulphide Precipitate (MSP).

“Our aim is to continue to responsibly service a burgeoning battery sector which is set to grow by nineteen times by 2030, according to a recent landmark report by the Global Battery Alliance, a public-private collaboration platform of about 70 international organizations, where ERG is a founding member,” added Mr Sobotka.